![]() Email:serena@machinehall.com

Email:serena@machinehall.com

Instant noodle production process(1)

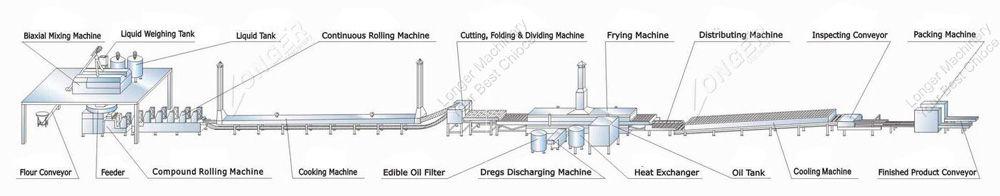

Instant noodle Processing line is as follows:

Aging and surface → → rolling → continuous rolling of composite molding → → cut off cooking → quantitative → fried → →→ air-cooled package

And a surface

And the surface is uniform mixing flour and water a certain time, a certain form a wet dough processing properties.

Rationale: When flour and water are uniformly mixed, flour gliadin and glutenin swelling, surrounded by wet gluten network. After some gluten network formation, stop Fighter, so as not to interrupt the network has been formed to start slow play, so that further expand and extend gluten dough thus formed has good processing performance.

Process requirements: good processing performance, full of flour evenly absorbent, loose particles, uniform size, uniform color was yellow flesh, free "flour."

Specific operations: flour premixed additive was added 1 minute, water was added quickly and evenly, with rapid stirring, for about 13 minutes, then slowly stirred for 3-4 minutes, forming a dough having both workability.

Impact and side effects of factors:

1) the quality of flour:

Flour wet gluten content requirements in 32--34%. Wet gluten content is low or poor quality will affect the wet gluten gluten network formation, dough flexibility, extensibility affected when rolling to a smooth, uniform thickness of the dough sheet formation cause difficulties, and will affect the taste and oil content of the finished product.

Flour ash content level, not only will affect the color and smell of flour, but also affect water and even when the surface of the flour, the impact of gluten network formation, have an impact on product quality.

In addition, the effect of particle size on surface and flour is also affected.

2) surface and the amount of water:

Protein flour, starch is only sufficient water, and in order to achieve good surface effect. Typically requires 100 kg of flour, add water about 30 kg, operations adjusted accordingly based on the water content of the flour, the water content of protein. Without affecting the tabletting and forming the premise of more water as much as possible, to improve product quality and favorable.

3) and the surface water temperature and the surface temperature and

And the surface temperature and the surface temperature is too low and the water molecules of low kinetic energy, protein, starch absorbent slow, gluten formation is insufficient. If the temperature is too high, it can lead to protein denaturation, resulting in reducing the number of wet gluten. Because the temperature optimum absorption of proteins at 30 ℃. When the room temperature below 20 ℃, promote the use of warm water and noodles.

4) adding salt

And when the surface appropriately added to dissolve the salt, not only flavor, but also to strengthen the gluten, improved dough processing performance. Salt dough while preventing rancidity effect. Usually: high protein content, more salt, add less and vice versa; high summer temperatures and more salt, add less in winter.

5) adding soda ash

When eaten in moderation, and added a base surface, can enhance the gluten, but it should not pay more.

6) and face time

And the surface has great influence on the length of time and surface effects. Time is too short, uneven mixing, gluten formation is not sufficient; too long, the dough overheating, protein denaturation, gluten quantity and quality is reduced. General and face no less than 15 minutes.

In addition, the stirring intensity and surface machine, will affect the quality of water and surface effects.

Instant noodle equipment is an automated machine used for instant noodles product

1, the operation is simple, with lighting, boilers, fuel can be, energy saving an

COPYRIGHT © 2010-2025 Instant Noodle Machinery